Micromanipulation for optical assembly– High-Precision Motion Control for Optical Assembly

What is Micromanipulation?

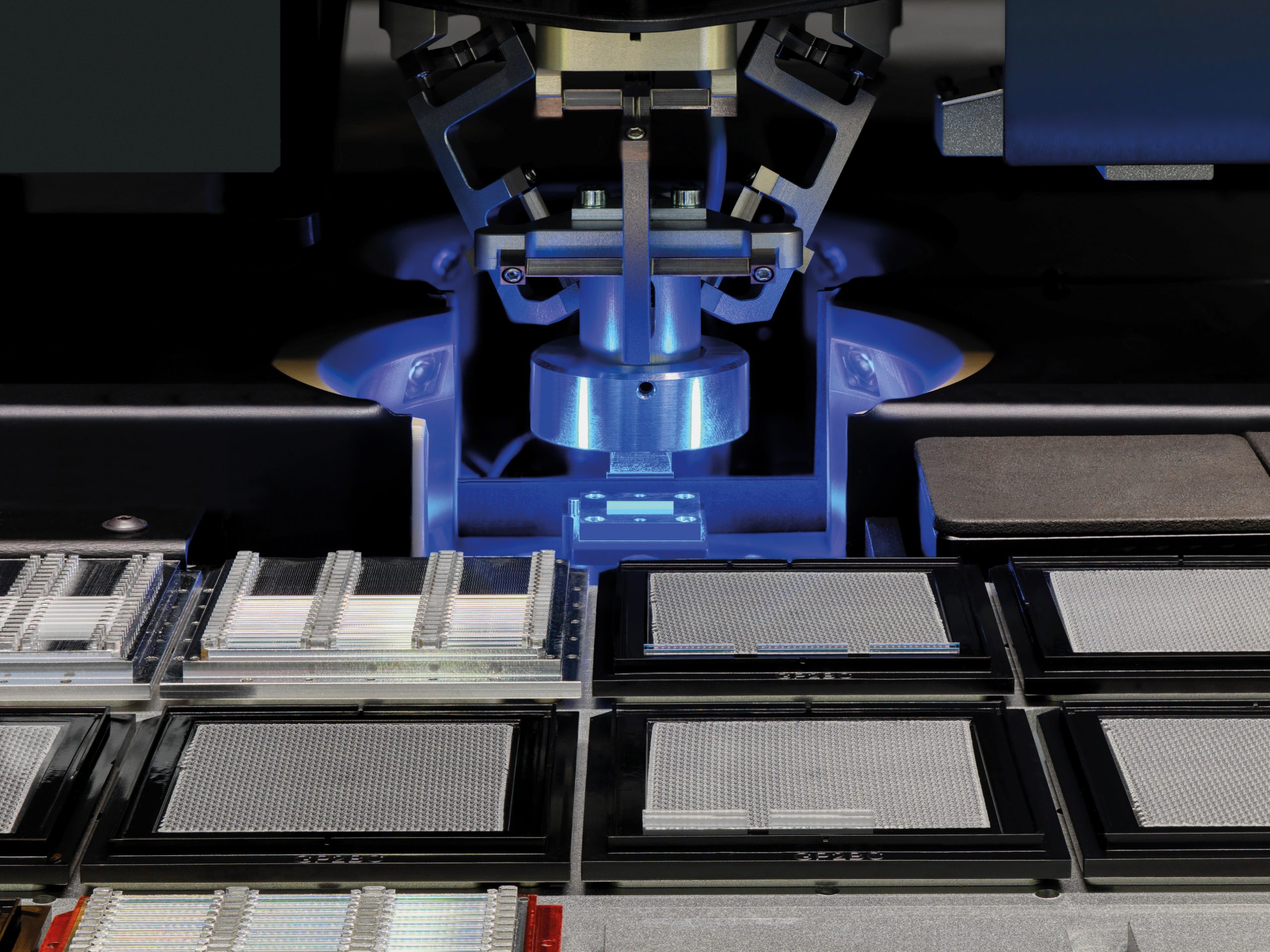

Micromanipulation for Optical Assembly is essential for high-precision manufacturing, ensuring sub-micron accuracy in positioning, alignment, and bonding of microscopic components. At Aixemtec, we integrate metrology and bonding technology directly into our micromanipulators, creating a single monolithic tool that enhances efficiency and precision in optical assembly processes.

At AIXEMTEC, we integrate metrology and bonding equipment directly into our micromanipulators, creating a single monolithic tool capable of measuring, aligning, and bonding optical components within a compact workspace. This advanced architecture enables us to perform active alignment while maintaining high efficiency and repeatability.

Beyond standard add-ons, our solutions can be enhanced with customer-specific adaptations to meet the unique requirements of different applications.

3D Micromanipulation for Optical Assembly – Six Degrees of Freedom with Outstanding Resolution

AIXEMTEC’s customizable micromanipulator technology offers exceptional step resolution across six degrees of freedom, ensuring ultra-smooth motion control without stick-slip effects. Proven in 24/7 automotive production, our micromanipulators deliver outstanding reliability and precision in even the most demanding environments.

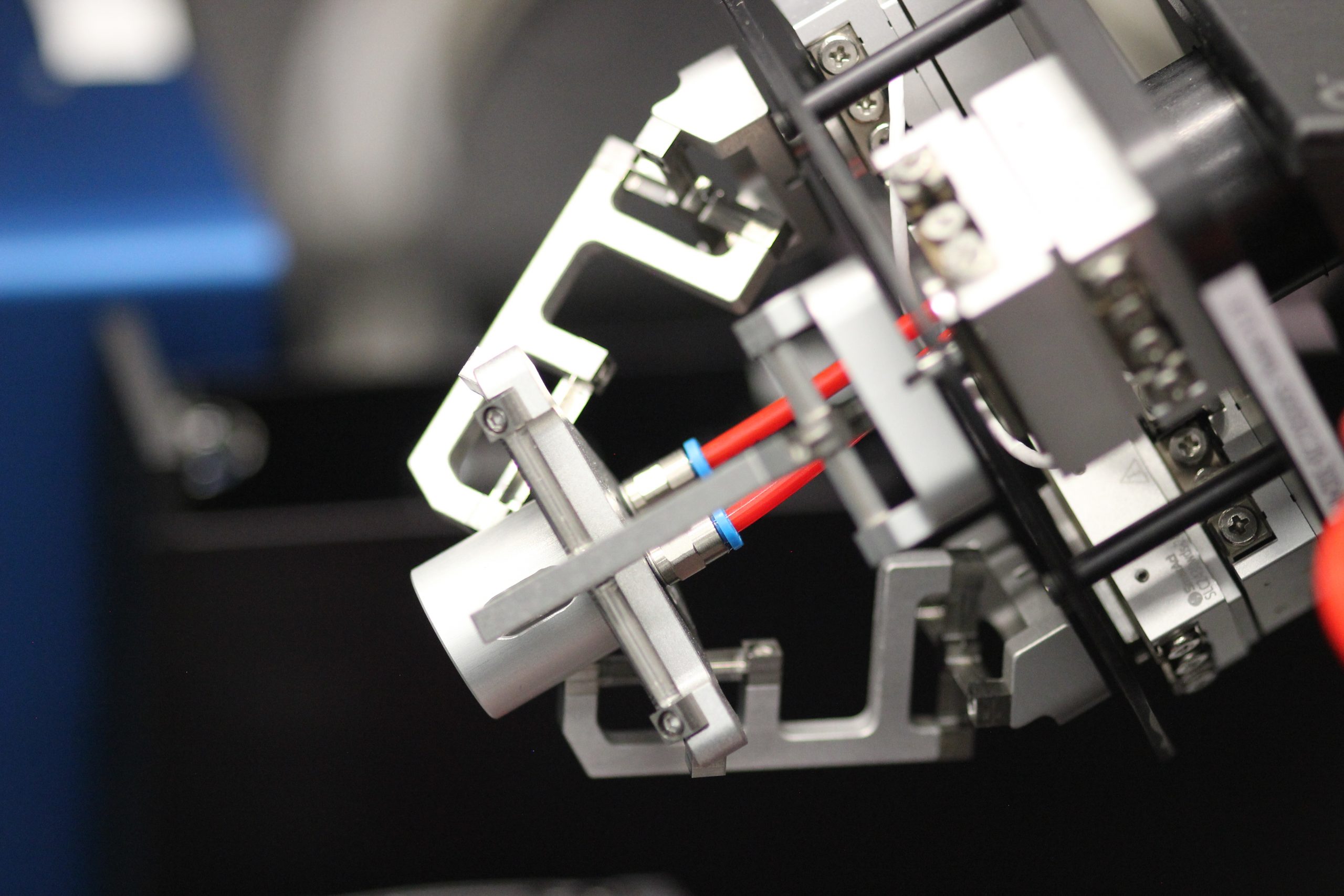

Thanks to our modular architecture, we can integrate and combine additional functions, such as:

- UV-illumination for adhesive bonding

- Customized gripping tools for various component shapes

- Integrated metrology setups for real-time quality control

Our micromanipulators can be used as stand-alone tools or seamlessly integrated into fully automated production systems.

Intuitive ConTrol:

With software-controlled pivot points, our micromanipulation tools can also be operated manually for enhanced flexibility and ease of use.

Micromanipulation with Functional Integration – A Compact All-in-One Solution

To minimize disruptions caused by using multiple tools, we integrate key electro-optical assembly and testing functions directly into our micromanipulation systems. This includes:

- Advanced gripping and metrology setups for various applications

- UV-illumination systems for precision adhesive bonding

The result is a fully customizable, compact, and monolithic tool designed for alignment, bonding, and testing. By maximizing the use of standard components while maintaining modular interfaces for custom enhancements, we ensure: