Services

One powerful way to maximize project success combines business-model of machine building and engineering services. By offering prototyping and small-series manufacturing services we solve multiple issues in production automation projects: Firstly, we can demonstrate and qualify the key enabling processes in feasibility studies. Secondly, we can help our customers to get hands on first prototypes and provide their developers or end customers with close-to production demonstrators and small series. Thirdly, we get to know your products in detail and can prepare a solid baseline for later turn-key production processes which makes machine projects much more effective and less risky.

Furthermore, also economically, this approach may positively influence your cash-flow, as investments in machines can be postponed to a later date.

PROTOTYPING

We understand that it can be challenging to take a product from an idea to a physical prototype, but that’s what we do best. We can help our customers showcase their products and the future production solution for scaling up to potential customers, investors, or other stakeholders at an early stage and give them a clear idea of what the final production will look like. Our goal is to help our customers bring their products to market as quickly and efficiently as possible, and our prototyping services are an essential part of this process.

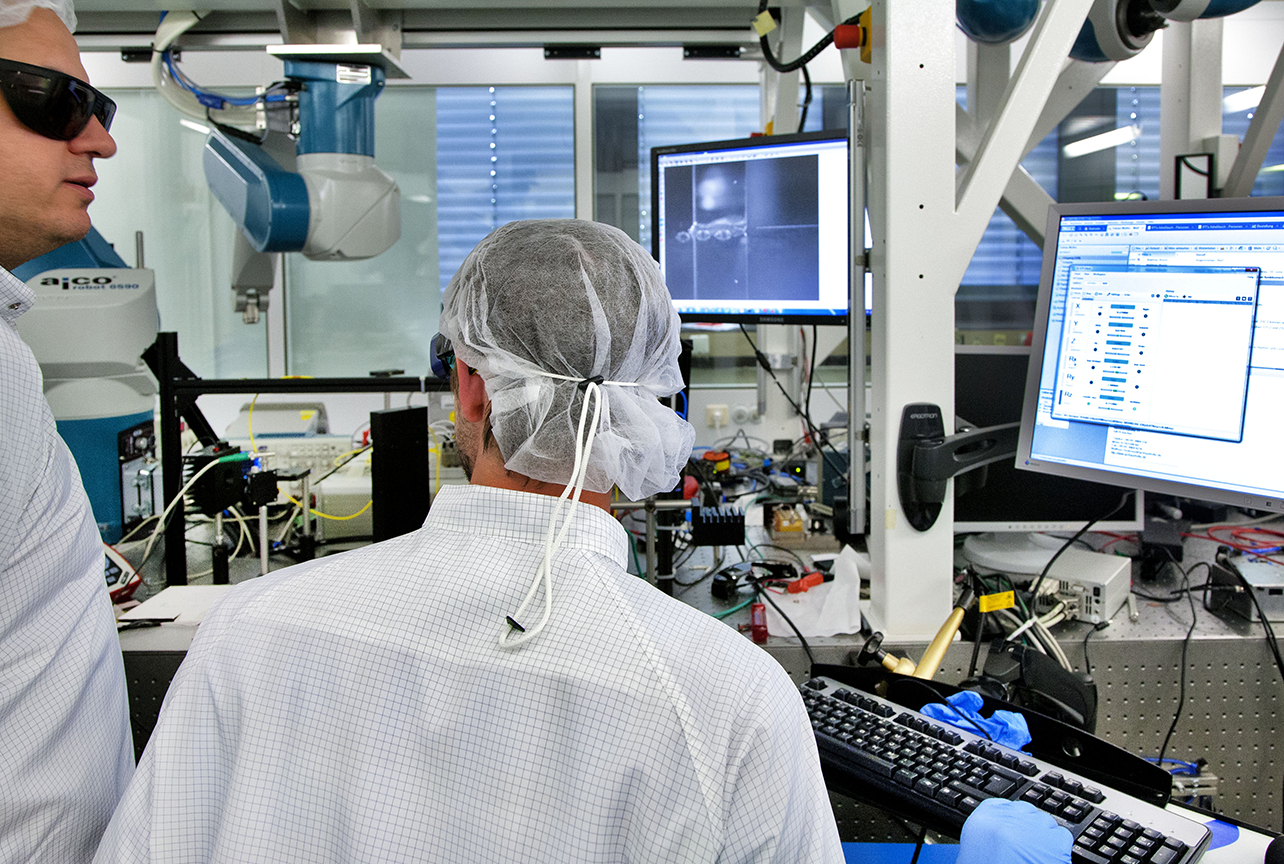

Our team is highly experienced in bringing high-end photonic systems and precision assembly products or prototypes to industrial production. Total costs of ownership can be largely influenced by the product design and the corresponding production processes. We work with our customers during the early stages of product development to not only provide our expertise but also give them a demonstration of a professional industrial production solution.

PROCESS DEVELOPMENT

We offer a wide range of process development services to help our customers achieve the highest quality, robustness, and productivity for their production solutions. Our team has a wide and high-tech toolbox of well-understood standard processes which we use to validate, adjust, or extend our process portfolio. The toolbox contains e.g. precision handling, ultra-precision dispensing and bonding, active, relative and passive alignment, customized metrology setups, sorting and inspection.

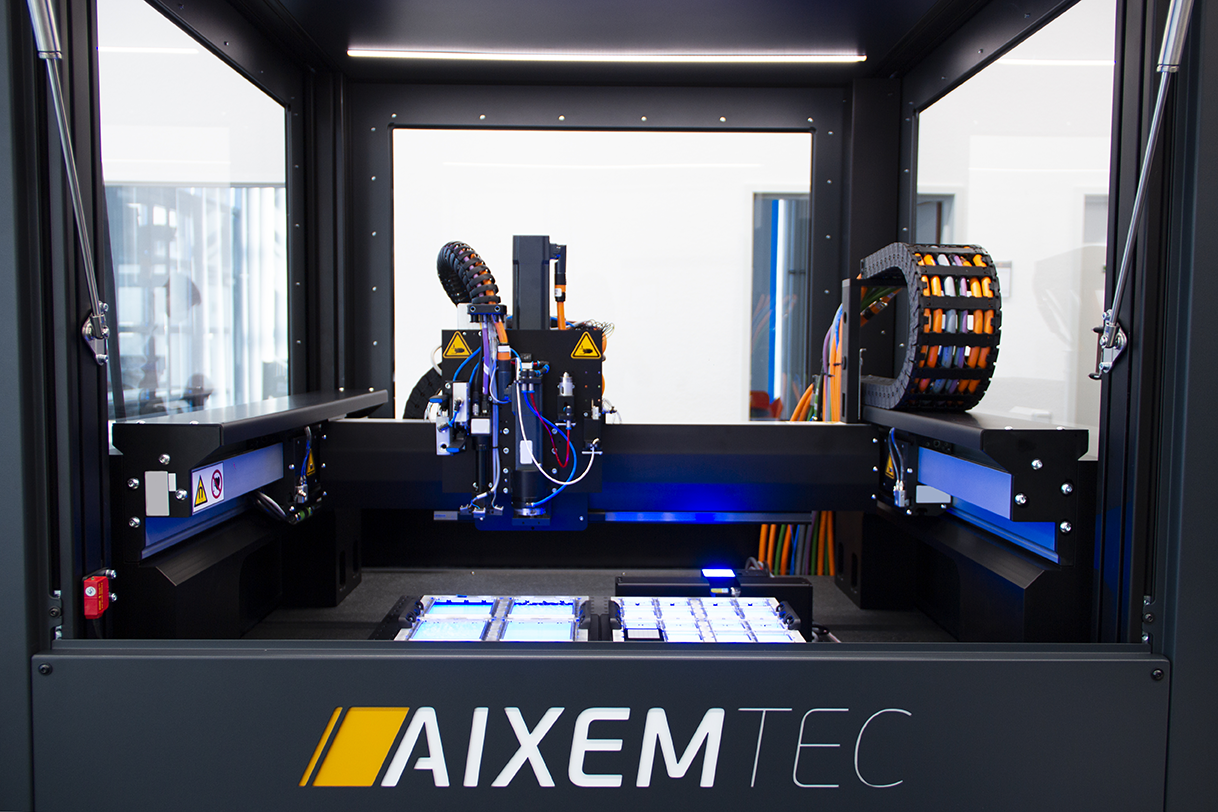

We understand that every product is unique, and sometimes our customers have specific process requirements that need to be met. On our stock machines we can assess those processes by reconfiguring them to demonstrate handling, dispensing, alignment or bonding processes which we jointly identify as the most critical ones.

Our key-enabler is our flexible software and seamless hardware integration throughout all our machine platforms and automation levels. This means your processes can be migrated between machine platforms and your production system can grow with the demands.

Mass Production

Want to stay fabless? Some customers decide to stay fabless and continue with contract assembly even after the product is established in the market. We work with qualified partners who can provide full production service in central Europe using our tools. This even expands the vertical integration e.g., to electronics SMT-integration.

Our team is well-versed in the intricacies of mass production, and we keep the requirements and boundary conditions in mind when building prototypes and everything in between. Also, we understand that mass production means something different for every market segment, and we are equipped to handle a wide range of production volumes.

For some products, mass production may mean producing one extremely complex item per day, while for others it may mean producing one item per second. Regardless of the production volume required, we have the capabilities to provide it, including machine platforms that can run at high speeds and execute processes in parallel to gain independence from the bottleneck processes. Component logistics in and out of the machines become very important at the latest stages of mass production, and we have implemented systems to ensure efficient and accurate logistics that allow us to maintain high levels of productivity.

Service & Support

We understand the importance of keeping your machines up and running. That’s why we offer a comprehensive service package to ensure that your machines are always in ideal working condition. Our service offerings include an online service desk, direct phone and Microsoft Teams support, as well as email support. We also offer on-site technician visits for repair services, and spare parts management to keep your machines running smoothly. Additionally, we offer Service Level Agreements (SLA) to provide you with the peacepeace of mind that your machines will be serviced quickly and efficiently in case of any issues. Our team of experienced technicians are dedicated to ensuring that your machines are running smoothly, so you can focus on what’s important – keeping your customers satisfied. Contact us today to learn more about our service offerings and how we can help keep your machines up and running.