Automation Level

The automation level needed for your application highly depends on the production volumes needed according to your current product life cycle. Starting with semi-automated production on desktop-based systems the transfer to a batch-based or continuous production on a higher volume platform can happen whenever needed. Therefore, we utilize the same tools and process building blocks on our different machine platforms. Gradually increase production volume capabilities by migrating your key processes to the appropriate machine ranging from one piece flow, through batch-based production into high-volume production lines.

Semi-automated

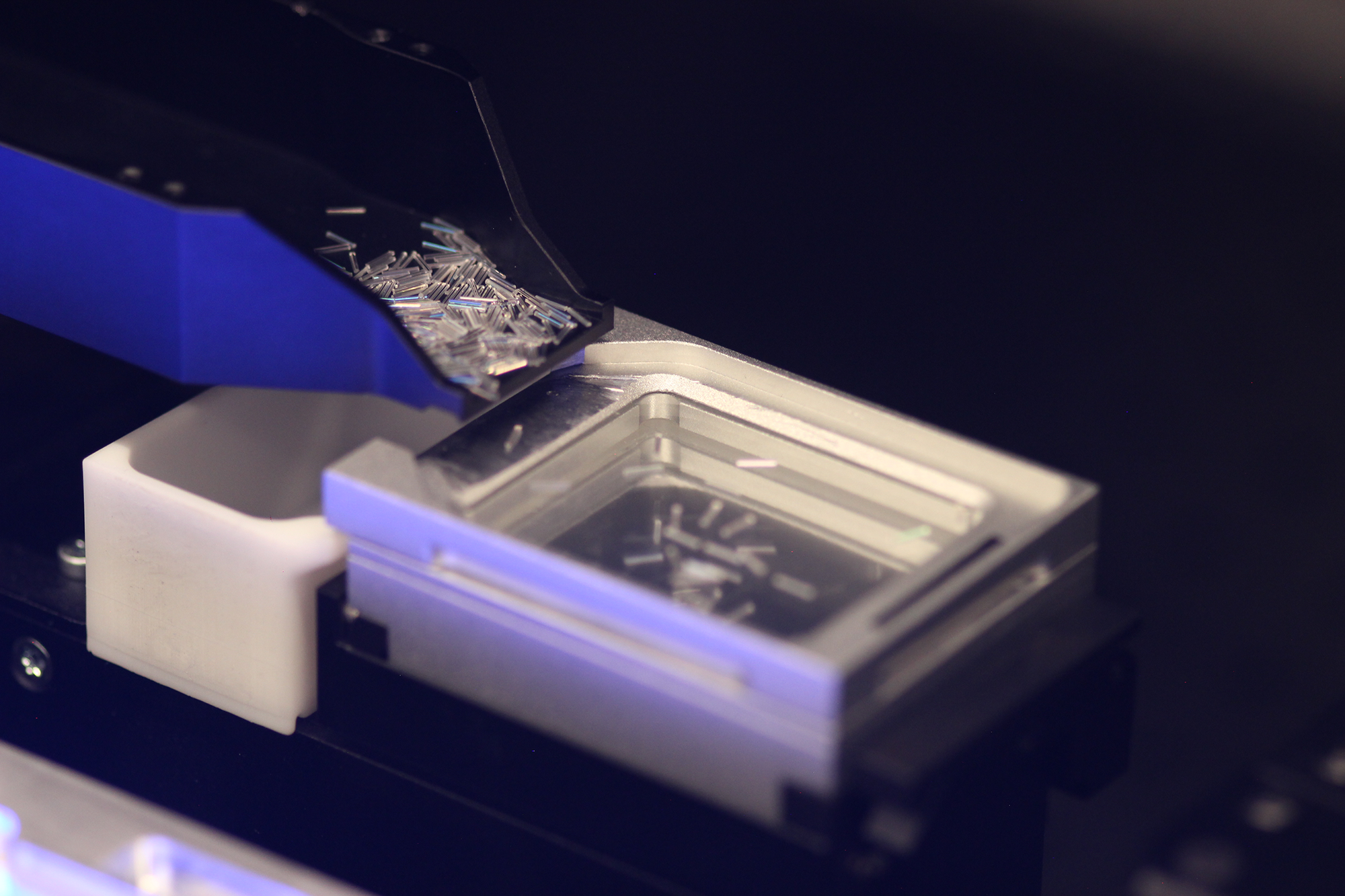

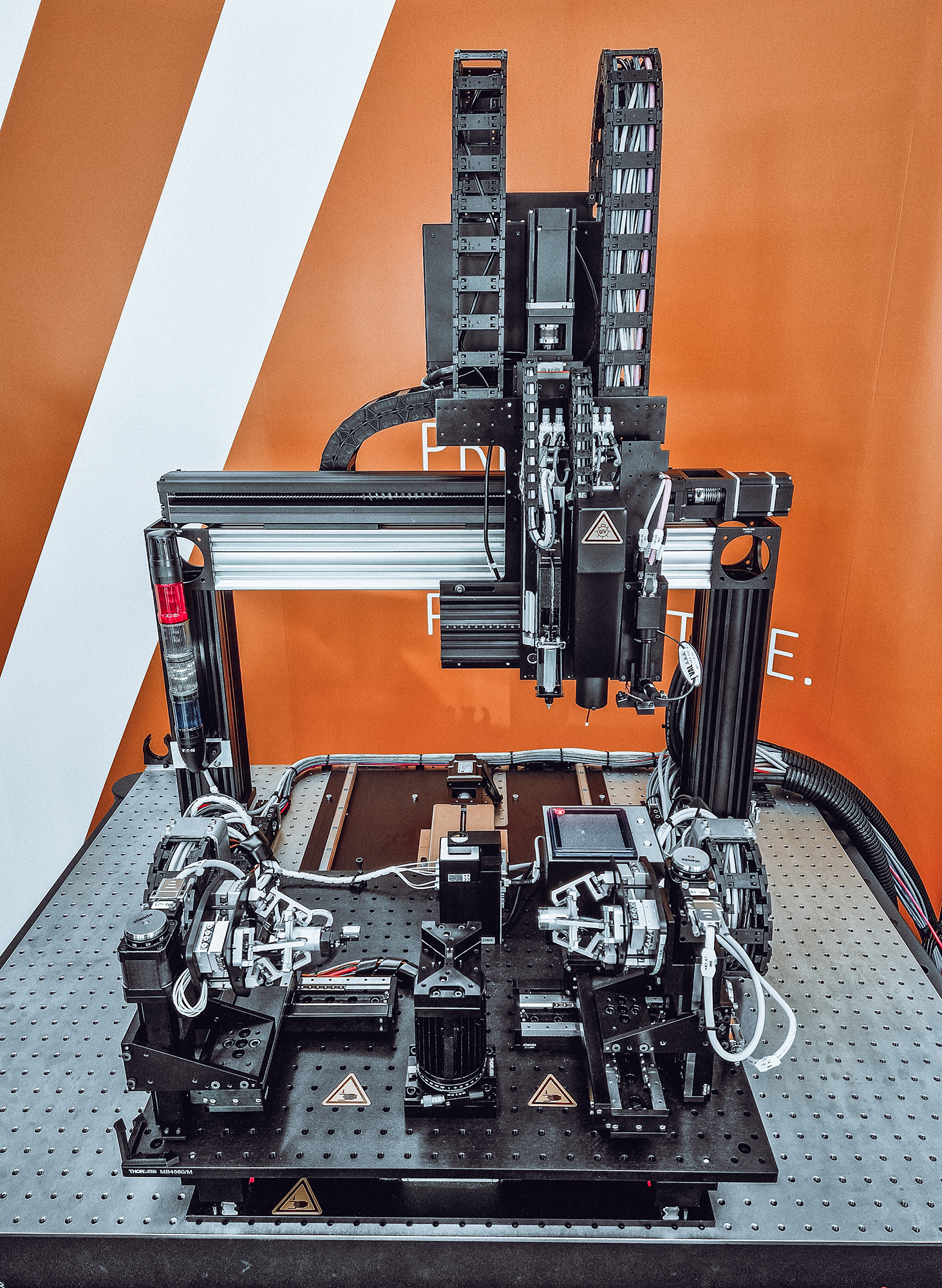

When developing new products or ramping-up production for launching of novel products the productivity or an autonomous production is in many cases not the main motivation for automation. In this phase flexible tools, allowing for easy modification to enable high process capabilities by automating the quality relevant processes are often needed. Typically, component logistics for part feeding can easily be covered by an operator. In miniaturized or optical systems, it can be advantageous to automate the handling by using our automation technologies. Furthermore, the alignment of two components by active, passive or relative alignment techniques is a main motivator to reach highest production quality. Finally making use of automated dispensing and bonding technologies can fundamentally increase your process repeatability and be an enabler to launch your new products in a cost-effective way. Whenever needed transfer your developed process building blocks to a batch-based or continuous production system.

Batch-Based

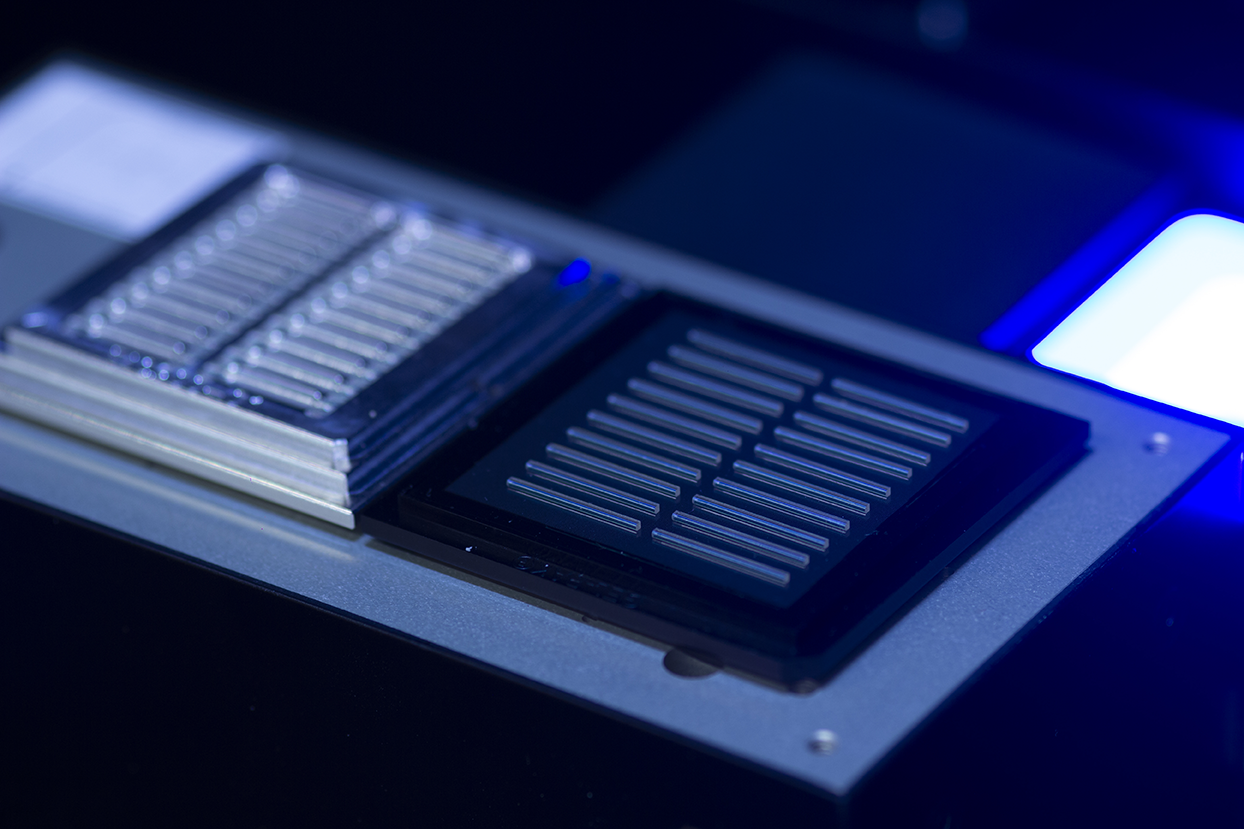

For typical production volumes in mid-volume a batch-based production scenario can be the most cost-effective way to process your components on your shopfloor. This requires fully chained processes in an automated production environment. Typically, operators feed trays into our machines which then process them automatically. The scope of such automation solutions is tailored to you needs and can provide sorting, inspection or assembly functionality. For moderate increase in production volume capabilities duplicate your turn-key solution. Take it one step further and add automated tray or component carrier feeders to a batch-based solution, or switch to parallelized processes in our production lines whenever your production volumes rise.

Continuous

Whenever your volumes increase, and you encounter the need for continuous production or long autonomous production times it may be the time to consider a production lines. Our line architectures are capable to execute processes in parallel: Integrate feeding, dispensing, alignment and bonding modules on demand. Eliminate the bottlenecks in your process flow by replicating the specific modules. Our production lines can have various forms. Upgrade your batch-based machine to a line by automated tray or component feeder integration.