Machine Configurations

We know that every customer is unique and has different needs for their production system, and that’s why we engineered a wide range of options to configure our machines. To meet the individual demands in an effective way, we created a highly configurable and modular machine framework and a set of standard tools and processes that can be combined to answer your current demands with a tailored solution.

Our various machine configurations provide the answer to our customers versatile requirements regarding their markets and applications.

Assessing the customer value stream and considering the automation level needed we jointly select the appropriate machine platform, select tools and processes for standard functions and thus define the machine configuration.

Thanks to our modular toolbox on the hardware side combined with a modern and powerful software that is used on all our machine platforms, we are able for quick and easy customization of our machines. Scalability is provided as tools and processes can be migrated to more productive solutions when needed.

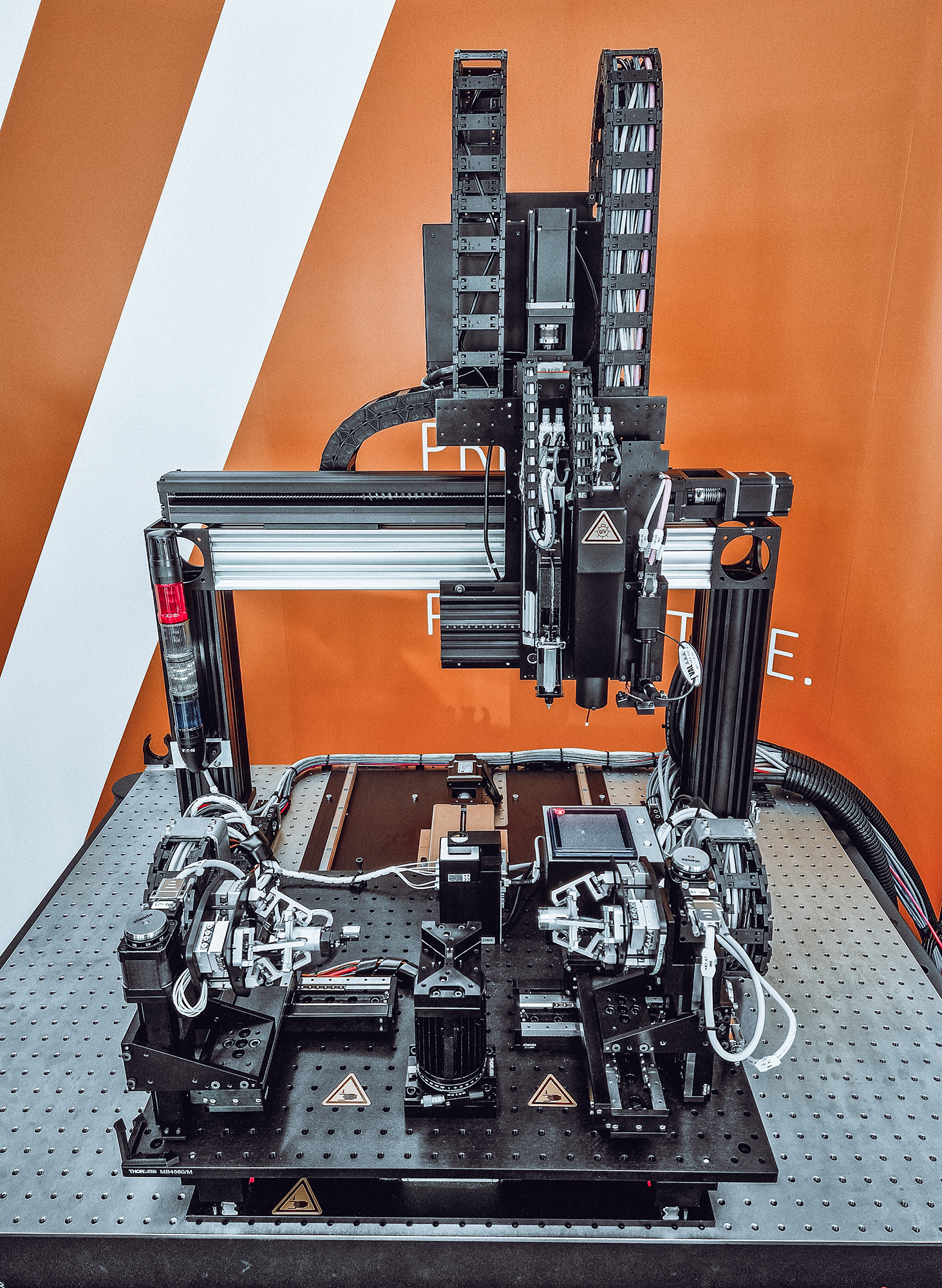

For IP-relevant and very early development applications in research and development environments we offer a high flexibility on hardware and software level. This approach is our enabler how to effectively serve both R&D and industrial production as an equipment manufacturer.

Sometimes, before taking design decisions qualification of key-enabling tools and processes may be advantageous. Make use of our prototyping and feasibility study services to best prepare your automation project.

Automation Level

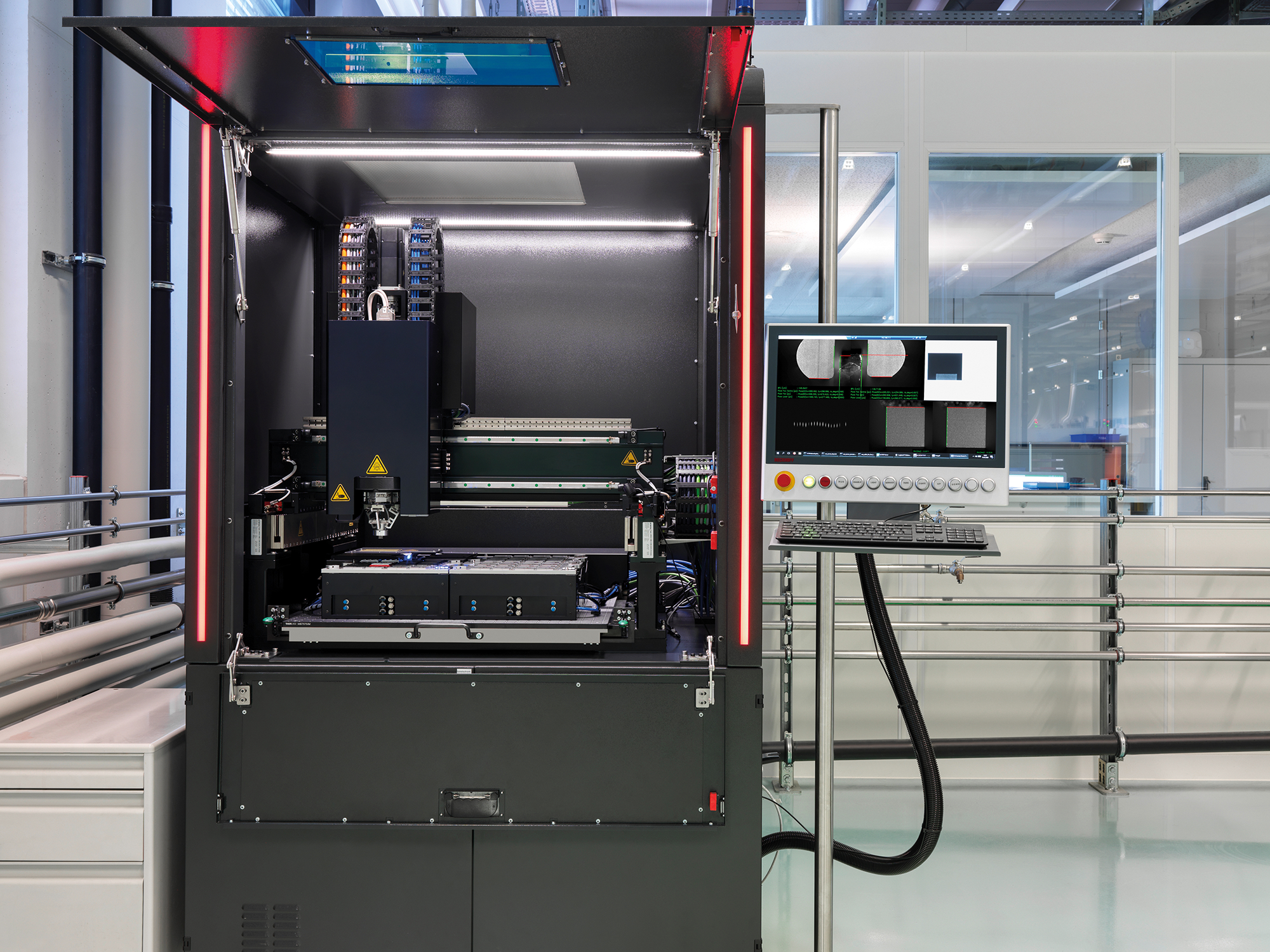

Different stages of product life-cycles require different production volume capacities. One software and platform independent hardware tools are our answer to effectively integrate appropriate automation levels matching customers’ requirements. Throughout the product life-cycle there may be different reasons for automation. Mostly thought of is increased productivity and yield. However, factors such as process capability in miniaturized systems, improved quality and process repeatability or independence from operators for scalability are also crucial in many cases. Recognizing the importance of these factors, we tailor our machine solutions to match the automation level needed for each customer and each product life-cycle phase.

MAchine PLatforms

A machine platform is our basis to create production systems tailored to your specific needs, consisting of a base machine which enables modular tool integration seamlessly on both hardware and software levels. We know that every customer has unique requirements, and we have engineered our system to be flexible and adaptable to those needs. One of the key factors in achieving this level of modularity of our tools and integration capability into our highly modern software. This means that as your needs change, your machine can evolve with you. With this flexibility, we offer a range of machine platforms to choose from. All solutions are utilizing the same hardware and software framework. This level of flexibility and scalability allows us to provide the best possible solution for your needs.

Standard Processes

On our standardized software and hardware framework we implemented a set of standard processes which are the baseline for every photonics production process. Fundamental process are self-calibration routines enabling a model-based processing of the components. All sensors and actors used in the machine can be addressed from our graphical user interface. Individual process building blocks for pickup, prepositioning, alignment and bonding are prepared in a standard framework. Sequencing of processes can be engineered in a comprehensive tool. Furthermore, we provide access to basic machine functions in a high-level scripting language provide wide options for customized sensor integration and process development to engineer your customized processes.

Your customized process

Make use of our powerful software environment to compose your customizes process flow by chaining our standard processes for typical automation tasks like handling, prepositioning, dispensing and bonding. Implement your product specific routines by parametrization of these process building blocks for the custom tools needed to process your components like grippers, fixtures and electronics. For more complex processes like active alignment routines, utilizing application specific sensors, we offer a high-level programming language interface enabling you to find high-end solutions based on standard and customizes process building blocks.