Precision Dispensing for High-Precision Assembly

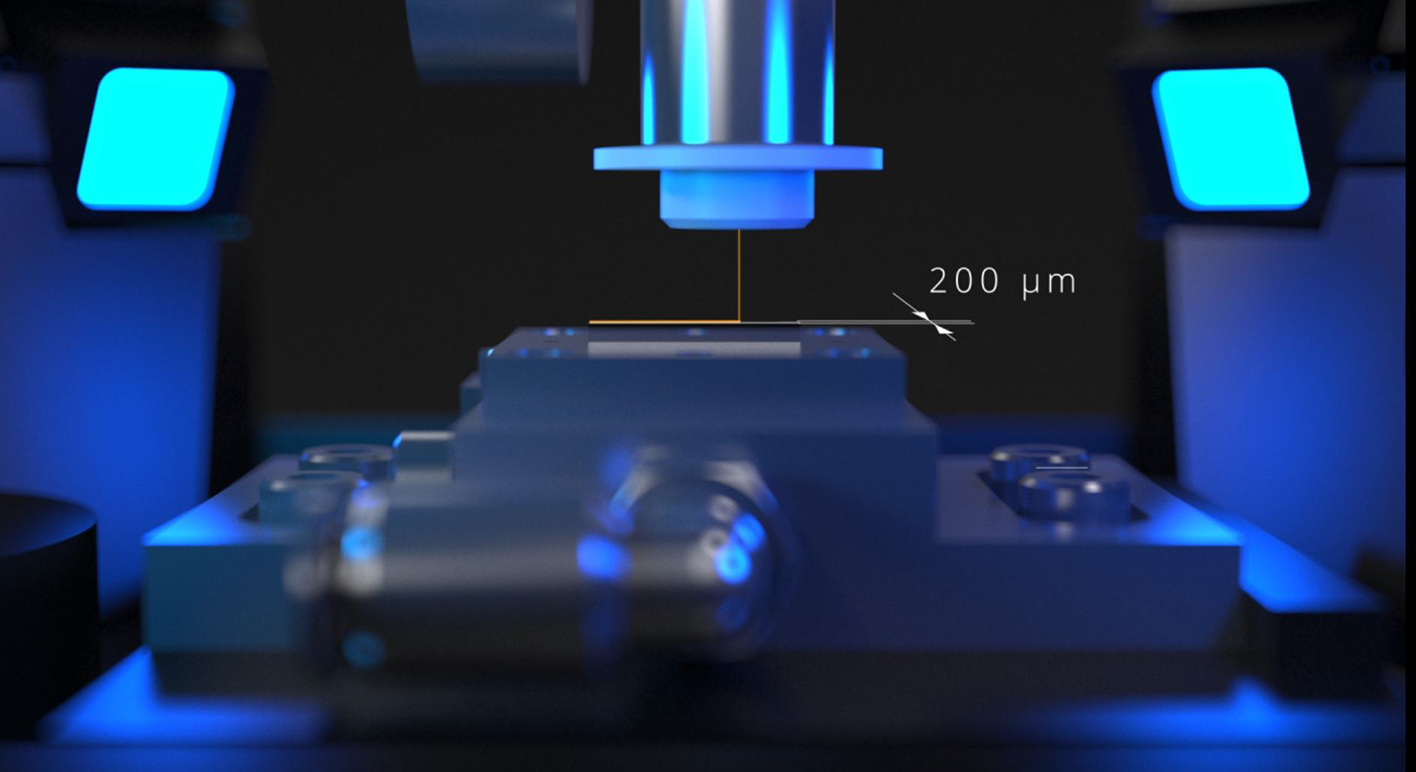

In precision assembly, the bonding process plays a crucial role, as it determines the final position of individual components. Adhesive bonding is the most common bonding technology for electro-optical systems, so a reliable dispensing process is essential to ensure exceptional product quality. A precise system ensures that the adhesive is applied exactly where needed, in the right amount, and at the right time. These challenges are significant, but we have successfully mastered the design of reliable dispensing solutions.

Our precision dispensing technology is particularly valuable in applications where accuracy, repeatability, and reliability are critical. Whether you are working with optical components, sensors, or microelectronics, our solutions ensure that each component is precisely bonded with minimal waste, improving production efficiency.

AIXEMTEC`s Dispensing Technologies for High-Precision Assembly

We integrate the most suitable dispensing technology depending on the application. This includes time-pressure dispensers and volumetric needle dispensers, which provide superior control for a wide range of bonding needs. For the smallest drop sizes, we use jet dispenser technologies, which are essential for micro-dosing applications, such as when working with tiny optical components or delicate materials.

To ensure a consistent, high-quality dispensing process, we equip our machines with automated calibration and cleaning functions. These systems monitor the dispensing process and ensure that every application meets the highest quality standards, reducing downtime and increasing throughput.

Our software also plays a crucial role in optimizing the dispensing process. It supports the identification of optimal dispensing parameters, such as pressure, flow rate, and dispensing speed. This helps speed up development cycles and reduces the trial-and-error approach that typically comes with adjusting dispensing parameters.

Additionally, we offer customized solutions for specialized dispensing requirements. Whether you need to work with materials that have specific viscosity requirements or apply adhesives in controlled environments, we can develop systems tailored to your specific needs. Remote monitoring options allow real-time performance tracking, giving you more control over your production line.

As a one-stop-shop solution provider, AIXEMTEC collaborates with trusted partners to perform environmental testing and ensure that all products meet necessary regulatory standards. From temperature and humidity tests to compliance with industry standards such as RoHS and REACH, we ensure that our dispensing systems are ready for any challenge.